UMBC’s carbon footprint includes two energy components: electricity consumption and stationary combustion of fuel (primarily natural gas). These two energy components, between 2007 and 2020, account for an average of 57% of UMBC’s Emissions ( ~35% from Electricity and ~ 22% from stationary combustion).

Moving forward, there is still much more work to be done to achieve UMBC’s ultimate goal of carbon neutrality, i.e., net-zero GHG emissions by 2050.

Campus Energy Emissions

In short, UMBC’s net-zero energy plan is to strategically 1) reduce energy consumption, 2) increase the percentage of electricity coming from renewable energy sources to 100% by 2050, and 3) offset any remaining GHG emissions via carbon offsets by 2050.

The first and ongoing mission of UMBC’s energy management strategy is reducing energy consumption. This is accomplished by enhancing ongoing energy conservation initiatives (such as Green Office Program, HVAC equipment scheduling, campus set point standards, and preventive maintenance); implementing new energy conservation initiatives (such as building analytics); utilizing energy performance contracts every ten to fifteen years as technology affords; and smart growth via improved space utilization and energy-efficient new construction. The conservation goal is to reduce campus energy consumption enough to offset the incremental energy demand associated with future campus growth. If successful, these conservation efforts will avoid 12,000 metric tons of new emissions being added to UMBC’s energy footprint.

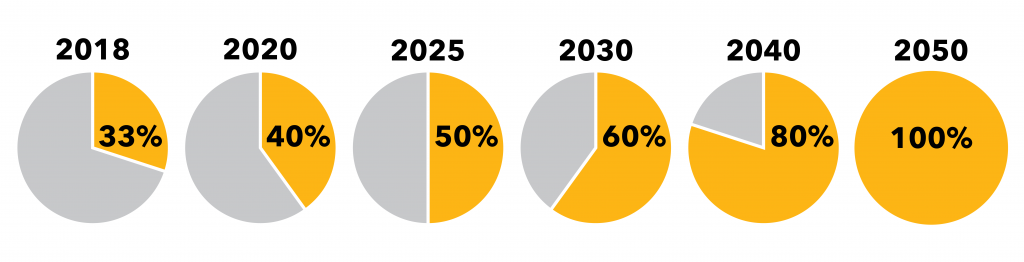

The second ongoing mission is to increase the percentage of UMBC’s electricity that comes from renewable energy sources. This is accomplished through the strategic procurement of wind and solar energy via Power Purchase Agreements (PPAs) and Renewable Energy Credits (RECs). UMBC will continue to explore options for onsite renewables, seeking a cost-effective blend of renewable energy procurement. The ultimate renewable energy goal is to get 100% of campus electricity from renewable energy sources. The interim goals are 40% in 2020, 50% in 2025, and 60% in 2030. When UMBC gets 100% of its electricity from renewables, UMBC will achieve net-zero electricity.

The third and final mission is to eliminate UMBC’s carbon footprint attributed to stationary combustion of natural gas and fuel oil. Reductions to stationary combustion will be accomplished via the aforementioned energy conservation strategies. After stationary combustion is reduced as much as reasonably possible, the ultimate stationary combustion goal is to offset all remaining GHG emissions via carbon offsets by 2050. By doing so, UMBC will achieve net-zero stationary combustion.

Collectively, operational improvements, behavioral changes, efficiency upgrades, technological breakthroughs, strategic investments, smart growth, renewable energy, and carbon offsets have the potential to eradicate UMBC’s energy footprint by avoiding 12,000 metric tons of new emissions and eliminating 50,000 metric tons of existing emissions.

Accomplishments before the 2007 Climate Commitment

UMBC has implemented many energy conservation initiatives over the years. Even before climate change and sustainability were mainstream issues, UMBC leveraged technology to conserve energy and reduce its impact on the environment. Saving 11 million kWh of electricity per year and 620,000 Therms of natural gas per year, energy-related initiatives implemented before the 2007 Climate Commitment proactively reduced UMBC’s carbon footprint baseline by 9,300 MTeCO2.

These innovative projects included the following:

- Upgraded pneumatic controls with Direct Digital Controls connected to a Building Automation System for better control of HVAC systems.

- Upgraded exterior lighting for roadways, walkways, and parking lots to more efficient metal halide lamps.

- Upgraded interior lighting from T12 to more efficient T8 lamps & ballasts and replaced incandescent bulbs with compact fluorescent lamps (CFLs).

- Converted air distribution systems in campus buildings from constant air volume to energy-efficient variable air volume (VAV) systems.

- Retrofitted cooling/heating systems in the Central Plant with high-efficiency chillers, boilers, and hot water pumps. These hydronic systems provide cooling and heating for two-thirds of the campus.

- Installed Thermal Energy Storage System at the Central Plant with 1.6 million gallon tank. Chilled water is produced at night, stored, and then used during the day. This reduces campus electric load during peak daytime hours, improving the reliability and efficiency of the region’s electric grid.

- Constructed Satellite Plant with high-efficiency chillers, boilers, and pumps to provide more efficient and reliable heating/cooling for residence halls and the dining hall.

- Installed variable frequency drives (VFDs) on large fan motors and large pump motors for more efficient operation, improved control and extended motor life.

Progress

2007 Baseline Carbon Footprint

UMBC’s 2007 baseline carbon footprint was 88,710 MTeCO2. The 2007 breakdown of greenhouse gas emissions by source showed 60.8 percent attributed to energy (46.2 percent from electricity and 14.6 percent from stationary combustion), 37.6 percent attributed to transportation, and the remaining one-point six percent attributed to other sources (solid waste, refrigerants, and agriculture). With energy being the largest contributor to UMBC’s carbon footprint, there was an immediate and continual focus on reducing energy consumption and greening the energy supply.

Lean & Green

There are two ways to reduce the carbon footprint attributed to energy: 1) use less and 2) get more from renewable sources. UMBC has done both!

- In 2007, UMBC used 77 million kWh of electricity with 3.5% from renewable energy sources.

- In 2018, UMBC used 65 million kWh of electricity with 33.3% from renewable energy sources.

From 2007 to 2018, UMBC’s gross square footage increased by 19 percent (more space to heat, cool, light, etc.) and student enrollment increased by 18 percent (more equipment plugged in, more students living on campus, more EVs being charged on campus, etc.). Based on this campus growth and associated electric demands, it would be reasonable for UMBC’s electricity consumption to increase by 15 million kWh. However, thanks to UMBC’s focus on efficiency and energy-related investments, UMBC’s electricity consumption decreased by 12 million kWh (27 million kWh less than unmitigated growth would have required).

In other words, despite significant campus growth, UMBC used 15 percent less electricity in 2018 than in 2007. Normalized to account for campus growth, UMBC’s electricity consumption per gross square foot (kWh/GSF) was 29 percent less in 2018 than in 2007.

Energy Conservation

The greenest kilowatt is not from wind or solar. The greenest kilowatt is not generated at all; it is the kilowatt that is no longer needed due to conservation efforts.

Conservation is defined as any reduction in energy consumption. Conservation can be achieved in many ways, ranging from complex technological upgrades that improve the efficiency of electrical/mechanical systems to simple behavioral changes such as turning off the lights.

Conservation is not glamorous, and most conservation efforts are invisible. Few ever see the high-efficiency chillers, boilers, and HVAC systems that have been installed to provide the air conditioning and heating for the campus. This equipment is safely out-of-sight in mechanical rooms, underground, on rooftops, or in ceilings.

Energy conservation initiatives implemented from 2008 to 2018 include the following:

- LEED Construction – Leadership in Energy and Environmental Design (LEED) is the most widely used green building rating system in the world. LEED provides a framework that project teams apply to create highly efficient, green buildings. UMBC is committed to designing new buildings and major renovations to meet or exceed LEED Silver standards. Explore UMBC’s green buildings with the virtual green building tour.

- Patapsco Hall Addition (LEED Gold)

- Apartment Community Center (LEED Silver)

- Performing Arts and Humanities Building (LEED Gold)

- UMBC Event Center (LEED Silver)

- Central Plant Boiler Upgrades – Replaced two hot water generators with high-efficiency units and stack economizers. The high-temperature/high-pressure hot water system provides heating for two-thirds of the campus.

- Green Office Program – The GO Program is a voluntary, sustainability certification program that provides resources to assist campus offices/departments in reducing waste, conserving energy, and promoting a culture of sustainability.

- Energy Performance Contracting – EPC is a means for implementing energy-saving projects that essentially pay for themselves over time via the associated energy savings. An array of energy conservation measures were carefully evaluated, and the following projects were selected based on operational needs and cost-effectiveness.

- Chilled Water Optimization upgraded chilled water distribution system that provides cooling for two-thirds of the campus. This project also included upgrades that enable the Thermal Energy Storage system to provide emergency chilled water distribution for critical cooling during a power outage. Completed in June 2013, this project generates annual savings of 5.7 million kWh and 3,100 MTeCO2.

- Lighting Upgrades retrofitted interior lighting fixtures throughout campus with more efficient lamps and ballasts, added occupancy sensors in many areas to automatically turn off lights, and upgraded lighting fixtures in all three parking garages with ultra-efficient LED fixtures. Completed in May 2015, this project generates annual savings of 6 million kWh and 3,200 MTeCO2.

Reducing energy consumption is an important and continuous effort. However, there is a practical limit to how much energy can be saved. The campus will always require energy to operate and serve UMBC’s educational and research needs. How can we mitigate or eliminate the “unavoidable” greenhouse gas emissions associated with essential energy consumption?

Renewable Energy

One of the suggested tangible actions listed in the ACUPCC is, “[w]ithin one year of signing this document, begin purchasing or producing at least 15 percent of our institution’s electricity consumption from renewable sources.” In May 2008, nine months after signing the ACUPCC, UMBC committed to getting 20 percent of its electricity from renewable sources. Initially, Maryland’s Conowingo Hydroelectric Plant was the primary source of UMBC’s renewable energy. Since then, UMBC has shifted toward Tier I renewable sources (wind and solar) and has been ramping up its renewable energy percentage.

Beginning in 2009, UMBC was involved in the State’s collaborative process for “Generating Clean Horizons,” a first-of-its-kind initiative to spur large-scale renewable projects in/near Maryland. Renewable energy production from Clean Horizons began in 2011. UMBC is buying Clean Horizons renewable energy via three Power Purchase Agreements (PPAs): Pinnacle wind, Roth Rock wind, and Mount St. Mary’s solar. These PPAs include the electricity commodity and the associated/bundled Renewable Energy Credits (RECs). Annually, UMBC gets about 10 million kWh from Clean Horizons PPAs, which is about 15% of the campus’ electricity.

To meet Maryland’s Renewable Portfolio Standard (RPS), the percentage of electricity that must come from various renewable sources each calendar year, UMBC purchases additional RECs as required. The remainder of UMBC’s renewable energy comes from the strategic procurement of voluntary Green-e certified RECs. In 2018, 33.3 % of UMBC’s electricity came from renewable energy sources.

UMBC’s renewable energy is being produced where it is most practical and on a large enough scale to make it economically viable. UMBC’s renewable energy strategy supports the triple bottom line—environmental, social, and economic performance—for true sustainability.

2018 Carbon Footprint

UMBC’s 2018 carbon footprint was 70,816 MTeCO2. The 2018 breakdown of greenhouse gas emissions by source showed 54.4 percent attributed to energy (33.5 percent from electricity and 20.9 percent from stationary combustion), 44.4 percent attributed to transportation, and the remaining one point two percent attributed to other sources (solid waste, refrigerants, and agriculture).

Comparing 2018 to the 2007 baseline, despite significant campus growth, UMBC’s reduced its carbon footprint by 17,894 MTeCO2, a reduction of 20 percent. Normalized to account for campus growth, UMBC’s carbon footprint per gross square foot (MTeCO2/GSF) was 33 percent less in 2018 than in 2007.

The only offsets through 2018 have been RECs, which by definition, are attributed entirely to electricity. Net electricity is total electricity consumption minus electricity from renewable sources.

Net emissions attributed to energy are net electricity (i.e., electricity minus RECs) plus stationary combustion.

- In 2007, UMBC’s energy footprint was (42,029 – 1,051) + 12,965 = 53,943 MTeCO2.

- In 2018, UMBC’s energy footprint was (35,549 – 11,850) + 14,826 = 38,525 MTeCO2.

By using less electricity and getting more from renewable sources, UMBC’s energy footprint has been reduced by 15,418 MTeCO2. Successful energy initiatives are responsible for 86 percent (15,414/17,894) of UMBC’s carbon footprint reduction through 2018.

It is worth noting that as one piece of the carbon footprint pie is successfully reduced, the other pieces of the pie will increase proportionally. For example, the reduction of electricity from 46.2 percent in 2007 to 33.5 percent in 2018, has contributed to increased percentages for stationary combustion (from 14.6 percent in 2007 to 20.9 percent in 2018) and transportation (from 37.6 percent in 2007 to 44.4 percent in 2018).

Although the carbon footprint associated with electricity has been significantly reduced, electricity is still the biggest single piece of UMBC’s carbon footprint pie. In the Future Energy Steps, there is a plan to get electricity to net-zero as well as stationary combustion to net-zero.

Future Steps

Past energy success and future campus growth make it more challenging to further reduce and ultimately eliminate the “unavoidable” greenhouse gas emissions associated with essential energy consumption.

UMBC has already implemented a vast array of energy conservation initiatives across the campus, resulting in significant energy savings. Most notably, UMBC’s electricity consumption per gross square foot (kWh/GSF) was 29% less in 2018 than in 2007. Since many big energy projects—all those with a reasonable payback—have already been implemented, the future challenge becomes identifying and implementing additional large-scale energy projects as future technological advances provide even greater efficiencies.

UMBC has already adopted LEED Silver as the design standard for the construction of new buildings and major renovation. This ensures the latest technologies are utilized to create very efficient, green buildings. However, even the most efficient buildings require energy to operate. Each square foot of building space added on campus increases the campus’ energy demand for cooling, heating, lighting, etc.

UMBC’s Master Plan includes new buildings that will add one million GSF, more than a 25 percent increase, over the next twenty years. Campus enrollment and students living on campus are also projected to have similar increases. Unmitigated, campus growth will result in a 25 percent increase in campus energy consumption and a commensurate increase in greenhouse gas emissions.

Energy Footprint

UMBC’s carbon footprint includes two energy components: electricity and stationary combustion. The 2018 breakdown of greenhouse gas emissions by source showed 54.4 percent attributed to energy (38,525 MTeCO2) with 33.5 percent from electricity (23,699 MTeCO2) and 20.9 percent from stationary combustion (14,826 MTeCO2).

Electricity is an essential power source for air conditioning, ventilation, lighting, and electrical/electronic equipment. In some campus buildings, electricity is also used for heating and domestic hot water.

Stationary Combustion refers to the onsite burning of fuel sources. For UMBC, this is primarily natural gas, which fuels boilers, heating equipment, cooking equipment, etc. UMBC also uses #2 fuel oil, but only rarely as it is for emergency/backup/temporary use, such as running emergency generators during a power outage or fueling Central Plant and Satellite Plant boilers during a natural gas interruption.

Net-Zero Energy

In short, the Net-Zero Energy Plan is to continually reduce energy consumption as much as reasonably possible, i.e., cost-effective and technically feasible; strategically increase the percentage of electricity coming from renewable sources to 100 percent by 2050; then lastly, offset any remaining “unavoidable” greenhouse gas emissions via carbon offsets by 2050.

UMBC’s energy strategy is to implement conservation initiatives—efficiency upgrades, operational improvements, and behavioral changes—sufficient enough to offset increases in energy demand associated with future campus growth. Doing so will maintain UMBC’s average annual energy consumption at 2019 levels, approximately 67 million kWh of electricity and 278,000 MMBtu of stationary combustion. These values will serve as estimates of UMBC’s essential energy consumption for forecasting the associated “unavoidable” greenhouse gas emissions that will require renewable energy and carbon offsets.

- To eliminate the electricity footprint, UMBC will ultimately need to get 100 percent of its electricity from renewable energy sources.

- To eliminate the stationary combustion footprint is more challenging and ultimately may require electrifying some heating processes, switching to biofuels, and/or carbon offsets.

UMBC’s goal is to have zero carbon footprint by 2050. This requires 1) Net-Zero Electricity by 2050 and 2) Net-Zero Stationary Combustion by 2050.

Net-Zero Electricity

Objective

Reduce and ultimately eliminate carbon footprint attributed to electricity.

Implementation Plan

a) Continue and enhance ongoing energy conservation initiatives.

- Green Office Program: Rollout to more offices and departments (increase participation by 25% from current inventory) and implement a periodic verification and recertification, every 4 years, for certified spaces.

- HVAC Equipment Scheduling: Setup/maintain HVAC equipment schedules in BAS to match the actual occupancy of each building, lecture halls, AHU zones, etc. Setup/maintain HVAC equipment schedules in BAS for campus holidays. Set vacant rooms in resident halls and vacant apartment units to unoccupied mode during winter/spring/summer breaks.

- Setpoint Standards: 70° F in heating mode. 76° F in cooling mode. Reheat valves to remain closed until space is below the heating setpoint.

- Setback for Unoccupied Mode: AHUs off unless space gets below 60° F or above 80° F

- Improved Preventive Maintenance for HVAC Equipment: Include a renewed focus on energy efficiency, such as changing filters and cleaning coils to improve fan efficiency and heat transfer, water treatment to improve pump efficiency and distribution capacity, finding/fixing leaks, and finding/fixing valves and dampers that are wasting energy. Proactive versus reactive

b) Utilize building analytics to identify energy-saving repairs and implement repairs (continuous commissioning). Analytic services for targeted buildings are to be included in the scope of the ATC service contract.

- Periodically (every 10-15 years) utilize energy services companies (ESCOs) to perform energy audits to identify potential large-scale energy projects that essentially pay for themselves via the associated energy savings, known as energy performance contracting (EPC).

- A typical EPC project takes about five years from inception to completion. Once complete, the payback period is typically ten years. Likewise, it generally takes ten years for new technologies to become technically feasible and cost-effective.

- Therefore, the estimated timing for future energy audits and potential EPC projects is 2022-2027, 2032-2037, and 2042-2047.

- Utilize State’s EPC contract to access pre-qualified ESCOs.

- Select and implement large-scale energy projects based on operational needs and cost-effectiveness.

c) Procure more electricity from renewable sources.

- Strategically increase the percentage of electricity coming from renewable sources to 100% in a cost-effective manner.

- Utilize a practical blend of offsite Power Purchase Agreements (PPAs), onsite solar, and Renewable Energy Credits (RECs).

- RECs provide the flexibility to meet annual goals.

Reduction Opportunity

Elimination of all Scope 2 emissions (35,500 MTeCO2)

Required Resources:

- Minimal extra funding is needed for ongoing energy conservation initiatives. Implementation will primarily utilize Facilities Management employees, the ATC contractor, and existing building automation systems (BAS). There will be some increased workload for personnel and Shops involved in implementation.

- Initially, minimal extra funding is to be needed for building analytics as the ATC contractor is to provide this as a part ATC service contract. Depending upon the scope, additional resources may be needed to perform additional analysis, utilize other vendors’ systems, add additional sensors, and implement recommended repairs/upgrades identified by the analysis.

- Minimal extra funding is needed for EPC investigation and implementation. The State’s EPC contract can be utilized to assign pre-qualified ESCOs to perform campus energy audits and EPC proposals. ESCO’s project development costs are typically rolled into the total project costs and paid back over time via the resulting energy savings. No upfront capital is needed, and there are no fees if the university opts not to proceed beyond the initial audit.

- There is a cost premium associated with renewable energy. Like other energy commodities, the price of RECs is set by the marketplace and varies depending on supply and demand for particular types of RECs, such as local vs national, Tier I versus Tier II, and source (hydro, wind, solar, offshore wind, etc.). Future REC prices are uncertain. In 2018, UMBC was able to purchase Green-e certified RECs for $1.00 each. At the other end of the spectrum, ORECs (for offshore wind) are over $130.00 each. Each REC represents the renewable energy attributes for 1 MWh of electricity. A reasonable, average estimate for RECs is $5.00 each. At $5/MWh, the premium to get 100 percent of UMBC’s electricity (67 million kWh) from renewables would be $335,000 per year.

Timeline:

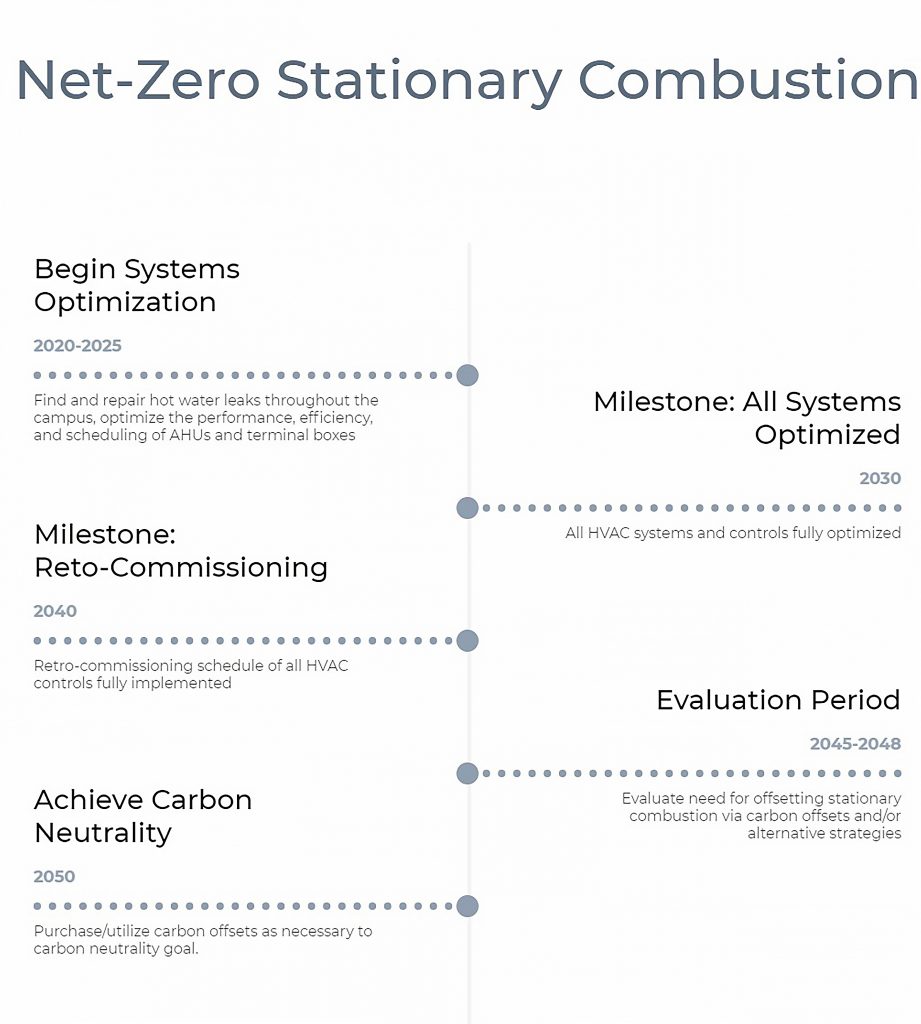

Net-Zero Stationary Combustion

Objective

Reduce and ultimately eliminate carbon footprint attributed to onsite, stationary combustion of natural gas and fuel oil.

Implementation Plan:

a) Find and repair hot water leaks throughout the campus.

b) Prioritize troubleshooting approach to find and repair obvious energy wasters.

- Utilize BAS to identify AHUs and rooms that are chronically overheating.

- When the chillers are off (economizer mode), utilize BAS to find AHUs and rooms that are overheating when there is no mechanical cooling to mask the leaking reheat.

c) Optimize the performance, efficiency, and scheduling of AHUs.

- Find and repair valves that are not sequencing properly and/or are not closing off when commanded closed.

- Find and repair dampers that are not sequencing properly and/or outside air dampers that are not closing when the unit is off.

- Setup/maintain HVAC equipment schedules in BAS to match the actual occupancy of each building, lecture halls, AHU zones, etc. Setup/maintain HVAC equipment schedules in BAS for campus holidays. Set vacant rooms in resident halls and vacant apartment units to unoccupied mode during winter/spring/summer breaks.

d) Optimize the performance and efficiency of terminal boxes.

- Find and repair reheat valves that are not closing off.

- Ensure that the heating mode setpoint is 70° F and that reheat valves remain closed until space is below the heating setpoint.

- Implement preventive maintenance plan and building analytics to routinely evaluate the operation of reheat valves and terminal box controllers.

- Adjust and improve HVAC controls and airflow parameters.

e) Implement a retro-commissioning schedule of HVAC controls.

f) Once maximum efficiency is achieved and stationary combustion is reasonably minimized, utilize carbon offsets and/or future technological breakthrough(s) to offset the “unavoidable” greenhouse gas emissions associated with essential stationary combustion.

Reduction Opportunity

Reduction of Scope 1 emissions by 15,000 MTeCO2.

Required Resources

- Minimal extra funding is needed for finding leaks or energy waste in the HVAC systems. Implementation will primarily utilize Facilities Management employees, the ATC contractor, and existing building automation systems (BAS). There will be some increased workload for personnel and Shops involved in implementation. Some repairs will require money for parts and/or subcontractors; however, these repair costs are not attributed to the CAP because the repairs are necessary to restore HVAC systems to working order.

- There is a cost premium associated with carbon offsets. The price of carbon offsets varies widely from less than $1 per ton to more than $50 per ton. The price depends on the type of carbon offset project, the carbon standard under which it was developed, the location of the offset, the co-benefits associated with the project, and the vintage year. A reasonable, average estimate for carbon offsets is $10 per ton. At $10/MTeCO2, the cost to offset 100% of UMBC’s stationary combustion (15,000 MTeCO2) would be $150,000 per year.

Timeline: